The total leakage capacitance of an ESS (Energy Storage System) is primarily calculated as the sum of the capacitances generated by the battery modules, cables, inverter, and cabinet structure . The sum of these capacitances is the leakage capacitance measured by the Insulation Monitoring Device (IMD).

Below is a table summarizing the leakage capacitance of each element based on a typical 1MWh-class ESS (DC 1000V system).

|

component |

Leakage capacitance range (approximately) |

explanation |

|

battery module |

0.5 ~ 2 µF/module |

Depends on the number of module cells and case insulation method |

|

Cable (DC Bus) |

20 ~ 60 nF/m |

Length and shielding structure influence, DC 100m → approx. 2~6 µF |

|

Inverter/PCS |

1 ~ 10 µF |

Parasitic capacitance due to EMI filter and DC-LINK capacitor |

|

Cabinet/Structure (GND) |

0.5 ~ 5 µF |

Electrostatic capacitance between metal case and ground, influence of panel area |

|

Others (sensors, communication lines) |

0.1 ~ 0.5 µF |

Parasitic capacitance of additional elements such as measurement lines and communication lines |

|

Total (1MWh class) |

5 ~ 50 µF |

There may be a ±20% deviation in actual measurements. |

That is, the total leakage capacitance of a 1MWh-class ESS is usually distributed in the range of 5 to 50 µF , and varies depending on the cable length, inverter capacity, and number of battery modules.

In ESS (voltage 1,000V, capacity 1,000Ah), **Leakage Capacitance (Ce)** is the parasitic capacitance that the battery cells, modules, cables, PCS, inverter, and wiring have with respect to the ground.

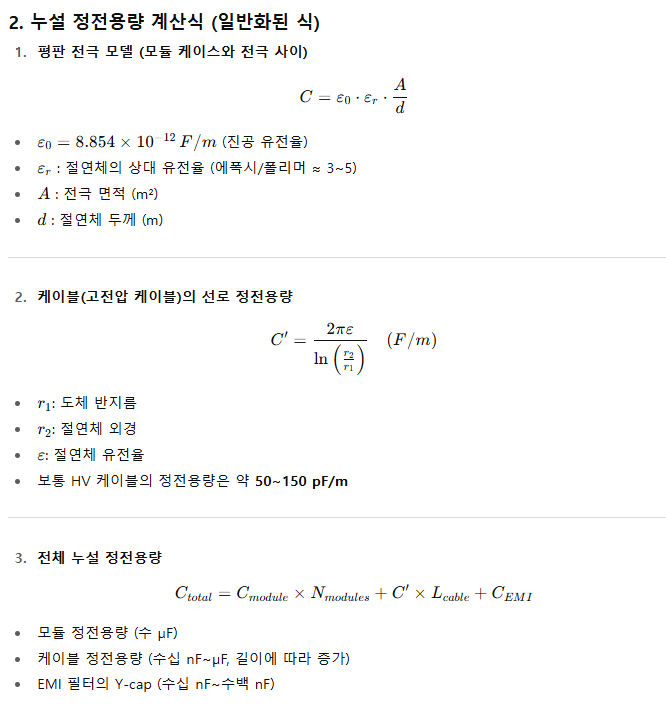

1. Causes of leakage capacitance

-

Between battery module/rack and metal case → Parasitic capacitance due to flat electrode structure

-

High voltage cable insulation and ground (GND) → line capacitance of the cable

-

PCS, inverter internal EMI filter → Y-Cap (Line-to-Ground Capacitor)

-

Cable length and layout → The longer the length, the greater the leakage capacitance.